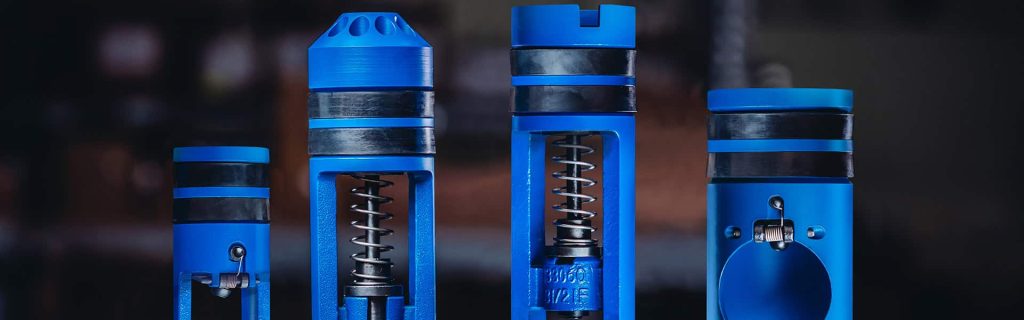

Drill pipe float valves, often referred to as “blue valves,” are meticulously engineered for exceptional performance and reliability. These valves effectively prevent drilling fluids, cuttings, and metal debris from returning up the drill string. Properly installed on the drill string, they significantly enhance blowout prevention measures.

Drill pipe (DP) float valves are offered in various configurations:

- Standard service

- H2S – 300°F service (HNBR/HSN)

- H2S – 400°F service

Each configuration is designed to meet specific operational needs, ensuring reliable performance under challenging drilling conditions.

We Distribute extensive range of DP float valves in various sizes. View our blue float valve sizes and models below:

10K Drill Pipe Float Valve

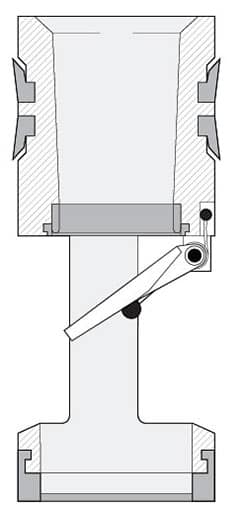

Plunger Style

The Model F is a plunger-type float valve designed to maintain continuous fluid flow during drilling while ensuring immediate shut-off if flow stops or reverses. Its piston seal effectively prevents backflow during connection breaks and helps prevent cuttings from entering the drill string, reducing the risk of bit clogging. The Model F is known for its economical operation and durable performance in regular drilling operations.

Model F sizes

| 2F3R |

|---|

| 3½IF |

| 4R |

| 5R |

| 5F6R |

10K Drill Pipe Float Valve

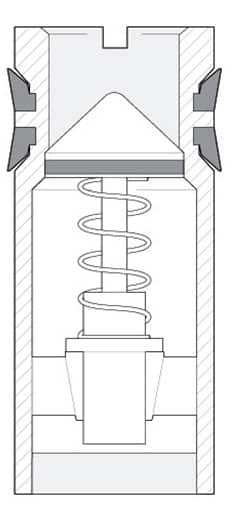

Flapper Style

The Model G is a flapper-type float valve designed to provide unrestricted flow through the valve, especially suited for abrasive drilling fluids. It closes to prevent cuttings from entering the drill string when flow stops and aids in pressure control alongside Blowout Preventer (BOP) equipment. Featuring an investment cast flapper, the Model G ensures quick opening for full flow capability. It remains fully open during joint retrieval from the hole, preventing drilling mud from spilling onto the rig floor.

| 2F3R |

|---|

| 3½IF |

| 4R |

| 5R |

| 5F6R |

7.5K Drill Pipe Float Valve

Plunger Style

The Model F is a plunger-type float valve designed to maintain continuous fluid flow during drilling, with the capability of instantly shutting off if flow is halted or reversed. Its piston seal effectively prevents backflow during connection breaks and ensures that cuttings are kept out of the drill string, thereby reducing the risk of bit clogging. Known for its economical operation and durability, the Model F is well-suited for regular drilling operations.

| 1R | 4R |

|---|---|

| 1F2R | 4F |

| 2F3R | 5R |

| 3F | 5F6R |

| 3½ IF | 6F |

7.5K Drill Pipe Float Valve

Flapper Style

The Model G is a flapper-type float valve designed to ensure unrestricted flow through the valve, specifically for abrasive drilling fluids. When flow stops, the flapper closes to prevent cuttings from entering the drill string and assists BOP equipment in controlling pressure within the string. Featuring an investment-cast flapper, the Model G opens quickly for full flow capability. It remains fully open when joints are lifted from the hole, preventing drilling mud from spilling onto the rig floor.

| 1F2R | 4F |

|---|---|

| 2F3R | 4FGS* |

| 3F | 5R |

| 3½ IF | 5F6R |

| 4R |

Repair Kits

10K Drill Pipe Float Valve

10K Style Repair Kits

7.5 K -Style Repair Kits

Includes: Springs, Seals & Guides

Where is a drill pipe float valve used?

Drill pipe float valves are essential components in the drillstring, which consists of drillpipe, drill rods, and other tubular products used in oil, gas, and water drilling, as well as utility construction for under-road and under-river crossings. Unlike other downhole pipes and tools, float valves do not feature threaded connections for screwing together.

Instead, the float valve is positioned inside the drill string, where a specially machined bore in one of the threaded connections accommodates it. This connection, known as a tool joint, securely holds the float valve in place. Its primary function is to ensure that fluid flow within the drillstring only moves in one direction—downward or away from the drilling rig—preventing any backflow.